A group of 35 engineers developed the R&D Test Systems’ 30MW test rig idea for ZF Wind Power

For ZF Wind Power’s Test Center 2024;

30MW powertrain assessments;

Back-to-back”: Components examined in parallel;

Simulating wind loading;

20MW generators;

MTS (NASDAQ:MTSC Systems Corporation)

— Ralf Nieschler, Key Account Manager, R&D Test Systems

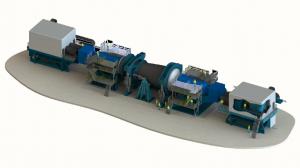

HINNERUP, DENMARK, September 27, 2022 /EINPresswire.com/ — In its largest order to date, Danish wind turbine test specialist R&D Test Systems will develop the 30MW powertrain and gearbox test bench for ZF Wind Power’s future “Test & Prototype Center” at Lommel, Belgium that may home the world’s strongest validation test bench for wind generators. Capable of simulating the multiplicity of wind hundreds {that a} nacelle powertrain would possibly expertise in its lifetime, the test rig, to be delivered in 2024, will assist enhance product reliability and shorten time to market.

“The wind loads, and directions can vary greatly, and each change creates loading on the nacelle powertrain,” says Ralf Nieschler, Key Account Manager, R&D Test Systems. “This new test rig must be much more powerful than the powertrain it tests, providing proof that the next generation of offshore turbines of, say, 20MW are capable of operating reliably in extreme offshore conditions over the defined lifetime,” he provides.

With its two 30MW motors, the test rig would be the world’s strongest powertrain and gearbox test bench and, at 60-meters lengthy, additionally the most important.

“The force of gusts wind can be a bit like a herd of elephants, pushing the blade around. This twisting and bending of the powertrain in all possible directions in the test rig will simulate the effect of 20 years of wind conditions in just a few months,” provides Nieschler.

Nacelle elements examined in parallel

The test rig employs the corporate’s “back-to-back” idea, the place two nacelle elements – for instance two powertrains or two gearboxes- are examined concurrently, main to important time financial savings.

Performing high-torque twisting, the 30MW motors are positioned on every finish of the nacelle elements beneath test. Additionally, a specifically designed load unit is positioned between the nacelle elements and gives the wind hundreds wanted to simulate the various real-world circumstances. Together the motors and the load unit can simulate not solely the harshest a great deal of wind but in addition the impact of wind coming from totally different instructions.

Despite weighing 5700 tons and with a drive torque of 45 million Nm – equal to the load of 30 household vehicles dangling from the top of a 100-meter turbine blade – and a bending second of up to 64 million Nm, the test rig can address test elements of various dimensions.

The test rig might be developed at R&D Test Systems’ headquarters in Denmark. In addition to electrical, techniques, software program and mechanical engineers, the undertaking will draw on civil engineering experience for the strengthened concrete basis that wants to be sturdy sufficient to face up to the intense fatigue and final wind hundreds throughout assessments in addition to the powertrain itself that may weigh a number of hundred tons.

A group of 35 full-time engineers have already began work on the test rig along with worldwide specialist suppliers. The test rig might be transported as particular person modules to Belgium. The undertaking makes use of R&D Test Systems’ in-house software program improvement group which can create instruments for the evaluation of the test information. Also, a part of the undertaking is a crane with a lifting capability of 300 tons for mounting of test powertrains into the rig.

Highly accelerated lifetime testing (HALT) expertise utilized

R&D Test Systems’ experiences in extremely accelerated lifetime testing (HALT), the place wind turbine prototypes are uncovered to the equal of 20 years of climate circumstances in a couple of months to uncover the bodily limitations of a design and confirm product reliability.

“To be awarded with a project of this size to develop the world’s most powerful powertrain test rig for wind turbines is a recognition of R&D Test Systems’ proven development expertise in specialised, large-scale and powerful test rigs in the wind power industry,” says Peter Ulrikkeholm, CEO of R&D Test Systems.

On stand Hall B1.EG, Stand 410, R&D Test Systems might be exhibiting its test vary at “WindEurope Hamburg 2022” 27-30 September 2022.

The R&D Test Systems is a global engineering firm that provides know-how improvement, digital test techniques, and turnkey large-scale test techniques for the wind business.

What makes R&D Test Systems distinctive is its expertise inside all product improvement phases – from improvement and design to constructing test services. R&D Test Systems makes use of its broad business data and extremely specialised engineers to strategy prospects’ challenges from quite a few angles to develop the appropriate resolution.

The ambition is to provide individualized, sustainable, and modern options that help its prospects’ corporations. That is how the R&D Test Systems creates worth by means of world-class engineering.

The R&D Test Systems is part of MTS Systems Corporation, which is owned by ITW.

Malene Conlong

for R&D Test Systems

+49 171 6992650

electronic mail us right here

![]()