Aircraft Tube and Duct Assemblies Market

Aircraft Tube and Duct Assemblies Market : Global Opportunity Analysis and Industry Forecast, 2023-2032

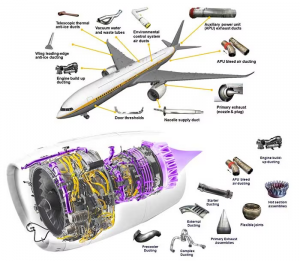

OREGAON, PORTLAND, UNITED STATES , July 20, 2023/EINPresswire.com/ — Aircraft tube and duct assemblies Market are essential portions of the aircraft fluid lines. Aircraft tube and duct assemblies are used for fluid passage solutions for systems in the aircraft. Tube and ducts are made from a variety of materials, including copper, aluminum alloy, steel, titanium, and other metals. Aluminum alloy, nickel alloy, corrosion resistant steel, or titanium tubes have replaced copper tubing in modern aircrafts, and they are now widely used in aviation fluid applications. The process of designing and assembling aircraft tube and duct so that they can withstand high water and air pressure, dangerous hot and cold temperatures, and corrosive chemicals. Aircraft manufacturers are concentrating their efforts on incorporating light-weight ducts and tubes into planes and helicopters in order to lower the overall weight of these equipment. Aluminum alloys are employed in lower temperature systems.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐏𝐃𝐅 – https://www.alliedmarketresearch.com/request-toc-and-sample/13578

The selection of aerospace materials is crucial in aerospace component and system design cycles. It affects many aspects of aircraft performance from the design phase to disposal, including structural efficiency, flight performance, payload, energy consumption, safety and reliability, lifecycle cost, recyclability and disposability. Aerospace structural material critical requirements include mechanical, physical and chemical properties, such as high strength, stiffness, fatigue durability, damage tolerance; low density, high thermal stability; high corrosion and oxidation resistance, as well as commercial criteria such as cost, servicing and manufacturability. Aside from satisfying basic service requirements, improving structural efficiency in aerospace structural design is becoming increasingly important since the use of lightweight structures improves aircraft performance. For instance, in aircraft tube and ductile market, the use of carbon fiber can reduce an airliner’s weight by 20%. The Airbus A350 XWB’s sweeping wingtips, which are made of carbon fiber, deliver roughly 5% in fuel savings. 50% of the airframe of the Boeing 787 Dreamliner, is made of carbon fiber.

The principle of lightweight design is to use less material or materials with lower density but ensure the same or enhanced technical performance. A typical approach to achieve lightweight design for aerospace components and systems is to apply advanced lightweight materials on numerically optimized structures, which can be fabricated with appropriate manufacturing methods. As such, the application of advanced lightweight materials can effectively achieve both weight reduction and performance improvement. Although metal materials especially aluminum alloys are still the dominant materials in aerospace application, composite materials have received increasing interest and compete with aluminum alloys in many new aircraft applications.

Structural optimization is another effective way to achieve light-weighting, by distributing materials to reduce materials use, and enhance the structural performance such as higher strength and stiffness, and better vibration performance. For instance, the Boeing 787 implements carbon fiber for achieving a 20% weight saving in aircraft which results in 10%–12% fuel efficiency improvement. Design optimization of a solar powered unmanned aerial vehicle (UAV) is an application of using both clean energy and lightweight structures to achieve green aviation operation.

𝐈𝐧𝐪𝐮𝐢𝐫𝐞 𝐁𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠 – https://www.alliedmarketresearch.com/purchase-enquiry/13578

𝐁𝐲 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧

Engine Bleeds

Thermal Anti-Ice

Pylon Ducting Enamel

Fuselages

Inlets/Exhausts

Environment Control Systems

Lavatories

Waste Systems)

Others

𝐁𝐲 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥

Steel

Nickel

Titanium

Aluminum

Composite

Others

𝐁𝐲 𝐑𝐞𝐠𝐢𝐨𝐧

North America (U.S., Canada, Mexico)

Europe (France, Germany, UK, Russia, Rest of Europe)

Asia-Pacific (China, Japan, India, South Korea, Rest of Asia-Pacific)

LAMEA (Latin America, Middle East, Africa)

𝐋𝐢𝐬𝐭 𝐎𝐟 𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬:

Flexaust, Inc.,

Unison Industries,

PMF Industries, Inc.,

Steico Industries,

Fiber Dynamics, Inc.,

Am Craft Manufacturing, Inc.,

Eaton,

Woolf Aircraft Products Inc.,

Leggett & Platt,

RSA Engineered Products LLC

𝐏𝐔𝐑𝐂𝐇𝐀𝐒𝐄 𝐅𝐔𝐋𝐋 𝐑𝐄𝐏𝐎𝐑𝐓 𝐎𝐅 – https://www.alliedmarketresearch.com/aircraft-tube-and-duct-assemblies-market/purchase-options

𝐊𝐞𝐲 𝐁𝐞𝐧𝐞𝐟𝐢𝐭𝐬 𝐨𝐟 𝐭𝐡𝐞 𝐑𝐞𝐩𝐨𝐫𝐭

✅This study presents the analytical depiction of the aircraft tube and duct assembly market along with the current trends and future estimations to determine the imminent investment pockets.

✅The report presents information related to key drivers, restraints, and opportunities along with challenges the aircraft tube and duct assembly market.

✅The current market is quantitatively analyzed to highlight the market growth scenario of aircraft tube and duct assemblies market.

✅The report provides a detailed aircraft tube and duct assembly market analysis based on competitive intensity and how the competition will take shape in coming years.

𝐒𝐢𝐦𝐢𝐥𝐚𝐫 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Commercial Aircraft Market – https://www.alliedmarketresearch.com/commercial-aircraft-market

Aircraft Lighting Systems Market – https://www.alliedmarketresearch.com/aircraft-lighting-systems-market

Aerospace Cyber Security Market – https://www.alliedmarketresearch.com/aerospace-cyber-security-market-A09068

David Correa

Allied Analytics LLP

1 800-792-5285

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

![]()

![[Toyota Times] Century as a Brand, Lexus as Innovation: All the Details on Toyota's New Project! [Toyota Times] Century as a Brand, Lexus as Innovation: All the Details on Toyota's New Project!](https://businessfortnight.com/wp-content/uploads/2025/10/Toyota-Times-Century-as-a-Brand-Lexus-as-Innovation-All-218x150.jpg)