Research highlights the feasibility of predicting 3D print quality from powder properties

Transitioning from ‘trial and error’ to a less expensive, sustainable method with the FT4 Powder Rheometer®

TEWKESBURY, GLOUCESTERSHIRE, UNITED KINGDOM, September 15, 2022 /EINPresswire.com/ — Researchers from De Montfort University (Leicester, UK) have efficiently correlated the quality of 3D printed polyamide specimens with powder properties measured with the FT4 Powder Rheometer® from Freeman Technology paving the method to extra cost-efficient, sustainable powder feedstock choice. Powders are presently chosen for 3D printing by way of print trials, however these are pricey, time-consuming, and wasteful. Key observations from this newest analysis are that the:

• quality of polyamide 3D printed specimens relies on the packing effectivity and flowability of the related powder feedstocks

• packing effectivity and flowability may be reliably differentiated by way of the measurement of bulk and dynamic powder properties with the FT4 Powder Rheometer

• key mechanical properties of printed specimens reminiscent of dimensional accuracy, tensile energy, and floor roughness correlate robustly with polyamide powder properties measurable with the FT4 Powder Rheometer

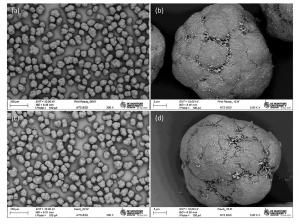

In the research, two business polyamide powders of related particle dimension and morphology had been used to provide 5 powder blends for testing. Measurements of dynamic properties – Basic Flowability Energy and Aeration Ratio – clearly differentiated the blends with respect to flowability whereas Conditioned Bulk Density values offered complementary perception on packing effectivity. Print trials with the powder blends utilizing a business Selective Laser Sintering system produced samples that various significantly with respect to mechanical properties. Observed variability was rationalized as regards to the measured powder properties and correlations had been established for key properties.

Improving the effectivity and sustainability of 3D printing are important to increase business utility. For powder-based processes a key purpose is the potential to characterise new and recycled powders to foretell behaviour in the printer, in addition to the properties of completed parts. This research provides to the rising weight of proof that implies the FT4 Powder Rheometer may help to grasp this purpose, for each polymeric and metallic powder feedstocks.

The De Montfort research is described intimately in a whitepaper freely accessible for obtain right here, or for a deeper dive into powder testing for 3D Printing/Additive Manufacturing strive the Freeman Technology e-book.

Jamie Clayton

Freeman Technology Ltd

+44 1684 851551

[email protected]

Visit us on social media:

Facebook

Twitter

LinkedIn

Other

![]()