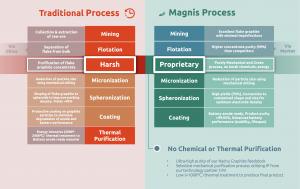

Magnis vs Traditional Process

Nachu CSPG Anode Key Properties

Nachu CSPG Graphite

Magnis plans to turn out to be a superior anode materials provider to satisfy the booming demand from the worldwide Lithium-ion battery market

Magnis Energy Technologies (OTCQX:MNSEF)

SYDNEY, NSW, AUSTRALIA, October 13, 2022 /EINPresswire.com/ — • Plans to ascertain a downstream anode energetic materials (AAM) processing plant with a variety of places within the US being investigated

• Plans to turn out to be a superior anode materials provider to satisfy the booming demand from the worldwide Lithium-ion battery market

• Strong alignment with Magnis’ imaginative and prescient of vertical integration of strategic property in Lithium-ion battery provide chain

• Secure provide of high-grade flake graphite feedstock from Magnis’ Nachu Graphite venture in Tanzania

• Innovative and sustainable graphite anode processing know-how eliminating harsh chemical and thermal purification

• Over 6 years of Pilot Plant testing in New York exhibits vital low-energy, low-cost downstream operations producing excessive performing supplies

• Advanced discussions with a number of potential offtake companions to supply and provide AAM

Magnis Energy Technologies Ltd (“Magnis”, or the “Company”) (ASX: MNS; OTCQX: MNSEF; FSE: U1P) is happy to announce its plans to ascertain a Lithium-ion battery Anode Active Material (AAM) manufacturing plant utilising prime quality and excessive purity pure graphite feedstock from its wholly owned Nachu graphite venture in Tanzania.

This downstream AAM manufacturing facility will ship a secured provide of one of the vital sustainable, cost-competitive, high-quality, and high-performance Coated Spherical Graphite (CSPG) anode merchandise within the market for the ever-growing US and European Lithium-ion battery market. The proposed AAM processing facility will strengthen Magnis’ imaginative and prescient of vertically integrating its strategic property throughout the lithium-ion battery worth chain, in addition to assembly the rising provide deficit of important supplies for the broader Lithium-ion battery market. Several places throughout the United States are at present being investigated.

Currently, Magnis is in superior discussions with a number of potential offtake companions to supply and provide AAM. Magnis has plans for the phased manufacturing of AAM, commencing with the operations of an indication plant adopted by organising a large-scale CSPG AAM manufacturing facility within the US within the subsequent 3 to five years. The demonstration plant goals to produce the AAM for the qualification course of with the OEMs and Lithium battery cell producers.

Nachu Flake Graphite

Magnis’ current profitable completion of the bankable feasibility research (BFS) replace confirmed the viability of the Nachu Graphite Project in Tanzania to supply and provide high-purity graphite anode feedstock at a industrial scale for the quickly rising Lithium- ion battery market.1

Magnis has constantly demonstrated the manufacturing of a excessive efficiency, industrial Lithium-ion battery grade (>99.95%) CSPG-based AAM from its Nachu graphite feedstock in Tanzania with the assistance of its strategic know-how companion, C4V.

Anode Technology

C4V and Magnis have developed a proprietary graphite anode processing know-how at its pilot facility positioned on the Binghamton University in New York working over the past six years utilizing lab scale tools.

C4V’s modern and scalable processing know-how which makes use of a purely mechanical downstream processing strategy has eradicated the necessity of any harsh chemical and thermal purification producing considerably low-energy and low-carbon footprint anode product in comparison with historically produced merchandise.

At the pilot facility, product has been consistently produced with greater yield (~70%) in comparison with the traditional graphite anode plant yield (~40-50%). Magnis’ CSPG AAM produced at C4V’s pilot facility has been validated in industrial graded cells by C4V and Magnis’ subsidiary Imperium 3 New York (iM3NY), which not too long ago commenced the industrial manufacturing of Lithium-ion battery cells at its Gigafactory facility in New York.2

Magnis has an unique licensing settlement with C4V to make use of and commercialize the AAM processing know-how globally.

Demonstration Plant

The demonstration plant will validate and show the scalability of Magnis’ AAM processing know-how at a industrial scale and can additional facilitate the enlargement to a large-scale manufacturing capability.

High Performing Results

Recent electrochemical battery efficiency of Nachu AAM has been extensively examined, validated and certified utilizing industrial graded Lithium-ion battery cells. These industrial graded cells have had over 1000 cycles whereas retaining over 90% of its preliminary cell capability which demonstrated a wonderful lifespan of the Nachu CSPG AAM and its readiness for the subsequent step of commercialisation.

Magnis Chairman Frank Poullas commented: “After many years of developing a process based on our Nachu Graphite we are excited to announce our plans to produce AAM materials.”

“We are assured that the intrinsic high-purity Nachu graphite feedstock comprising of huge crystal construction with minimal imperfections and C4V’s distinctive processing know-how will produce and ship a superior AAM product in comparison with the rivals within the market.

“With the huge shortage of AAM in the marketplace right now, we look forward to producing sustainable, cost competitive and high quality anode materials.”

Group Communications Manager

Magnis Energy Technologies

+61 426 042 590

[email protected]

![]()