DCS and Metrologic mix to present a whole high quality resolution

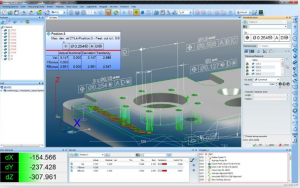

3DCS Variation Analyst Software for GD&T Creation

Metrolog – Read in GD&T, See Tolerance Zones, and Utilize for Programming

With a digital tour now obtainable, DCS and Metrologic are bringing imaginative and prescient into actuality for all to see

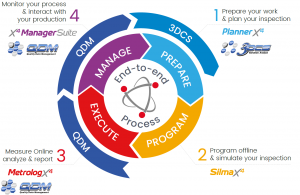

CHICAGO, ILLINOIS, UNITED STATES, October 12, 2022 /EINPresswire.com/ — Dimensional Control Systems (DCS) and Metrologic Group collaborated at IMTS 2022 within the McCormick Center, Chicago, Illinious, to reveal how a closed loop high quality system may look. Combining their know-how into an End-to-End Quality Solution brings actuality to the imaginative and prescient of Quality 4.0 and the Digital Twin.

At IMTS, DCS and Metrologic wished to give guests the possibility to see what a closed-loop manufacturing course of appears like in observe. This was, after all, a microcosm of what happens at a plant or giant enterprise, however seeing the totally different items and how Quality 4.0 might be leveraged to drive info downstream from design is a precious imaginative and prescient that’s typically mentioned, and hardly ever proven.

Here is your probability to see it –>

There is quite a bit to see right here, so let me break it down for you.

3DCS – Designing Robust Models and GD&T

During the digital design part, 3DCS, a variation analyst instrument built-in into CAD, gives the instruments to check, simulate, and create strong designs. The output from these fashions is a set of optimized GD&T, that’s, arrange to cut back manufacturing prices in non-critical areas, and honed for areas discovered crucial to high quality and at danger of non-conformance. This output GD&T is the driving pressure of the method, related to CAD and machine readable for consumption downstream.

Silma – Advanced Simulation and Digital Twin of your 3D Measurement Process

The GD&T created and optimized in 3DCS is then handed to Silma, which creates a measurement plan from the info. This plan might be programmed offline, holding your line operating whereas programming takes place. The program routinely interprets the GD&T, which might be nearly examined, making certain that it’s error- and collision-free as soon as utilized to the manufacturing course of. In addition, its collision detection and computerized collision elimination instruments provide the skill to visualize, optimize and replace in actual your complete program probing path. Once full, the measurement program is distributed to Metrolog and your machines.

Metrolog – The Most Powerful Metrology Software with Any Device

Whether you’ve got a Wenzel CMM, a FARO measurement arm, a imaginative and prescient scanning system, Metrolog can make the most of your measurement plan and make it a actuality. With a plethora of instruments for improved efficiency, Metrolog simplifies the day-to-day measurements and gives distinctive outputs to view the info earlier than sending it downstream.

• Metrolog X4 has a brand new geometric and dimensional tolerances processing engine for dealing with probably the most advanced instances in report time.

• Geometric tolerance definition facilitated.

• “Expert” system making certain the proper analysis methodology and outcomes.

• Total help for the tolerance analysis in compliance with the given commonplace.

• Support for ANSI and ISO requirements.

• Certified and acknowledged resolution by the PTB and NIST organizations.

The PMI and GDS&T is now an information set from the half displaying it’s conformance to specification. This is then repeated for 30 extra elements, inline, or primarily based on a company’s high quality requirements.

i-Robot – Automated Measurement Programming for Best Results

If you’re planning on utilizing a robotic to measure, the i-Robot know-how is appropriate for all industrial robots; it gives a production-ready metrology resolution that’s correct, dependable and versatile.

i-Robot is completely fitted to all functions requiring flexibility and productiveness whereas offering excessive metrological accuracy.

• Measuring accuracy totally unbiased of robotic’s positioning precision.

• Robot actions completely

• synchronized with measurement.

• Robot trajectory totally managed by i-Robot half program.

• The important functions might be discovered within the automotive, aerospace and their suppliers for continuity throughout manufacturing strains and metrology management.

The outputs, very similar to with Metrolog, present perception into your half’s conformance to spec, permitting the info to be displayed in numerous codecs to make it straightforward to interpret.

These outputs are then learn in by a QMS – Quality Management System – to present a real-time understanding of the applications and entry to highly effective SPC for drawback prediction and root-cause evaluation.

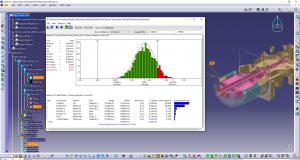

QDM SPC Platform – Real-time Quality Monitoring, Alerts, Dashboards, and Reports

QDM reads the info in as it’s being accomplished by your machines. Metrologic know-how seamlessly feeds the system to stick with it to date with minute by minute outcomes, offering your staff actual perception into your total high quality. View that information as customizable dashboards and SPC stories, or depart it out of thoughts till the system detects the beginning of an issue the place it would alert all stakeholders and present perception into the guts of the difficulty. This permits your staff to concentrate on what they do greatest, with out having to consistently sift via lengthy Excel sheets of x, y, z coordinates and outputs. Graphical stories and screens immediately present the place issues are, after they started, and the place within the manufacturing course of.

Should a difficulty that can’t be shortly resolved come up, the measurement information might be shortly despatched again to the design group for simulation and evaluation, testing an answer to show out its success earlier than shifting ahead.

Join DCS later this month to see how PMI is handed from Design to Metrology with DCS’s webinar

Click Here to Learn More About Setting Up a Connected System by Registering

About Dimensional Control Systems, Inc

Dimensional Control Systems Inc. (DCS) primarily based in Troy, Michigan, USA is concentrated on the methodology of Dimensional Engineering. DCS provides best-in-class software program options and companies to manufacturing firms the world over. With over 50 years of Dimensional Engineering background, DCS repeatedly strives to exceed our buyer’s expectations for world-class Variation Analysis and Quality Management System (QMS) software program and companies.

About Metrologic Group

Metrologic Group designs and sells 3D measurement software program options, digital gadgets and associated companies. The group gives revolutionary industrial options and merchandise for measurements, the place accuracy ranges from micrometers to millimeters.

Metrologic Group’s options are designed primarily for the automotive trade, aerospace, industrial manufacturing, client merchandise, energy technology and the medical industries…

Founded in 1980 in France, Metrologic Group is now a worldwide firm with 6 subsidiaries and 18 licensed resellers, overlaying greater than 35 totally different nations.

Benjamin Reese

Dimensional Control Systems

+1 2482699777

e-mail us right here

Visit us on social media:

Facebook

Twitter

LinkedIn

Other

Closed Loop Manufacturing with the Digital Twin at IMTS – Dimensional Control Systems and Metrologic

![]()